Hotline

Hotline Consult Now

Consult Now

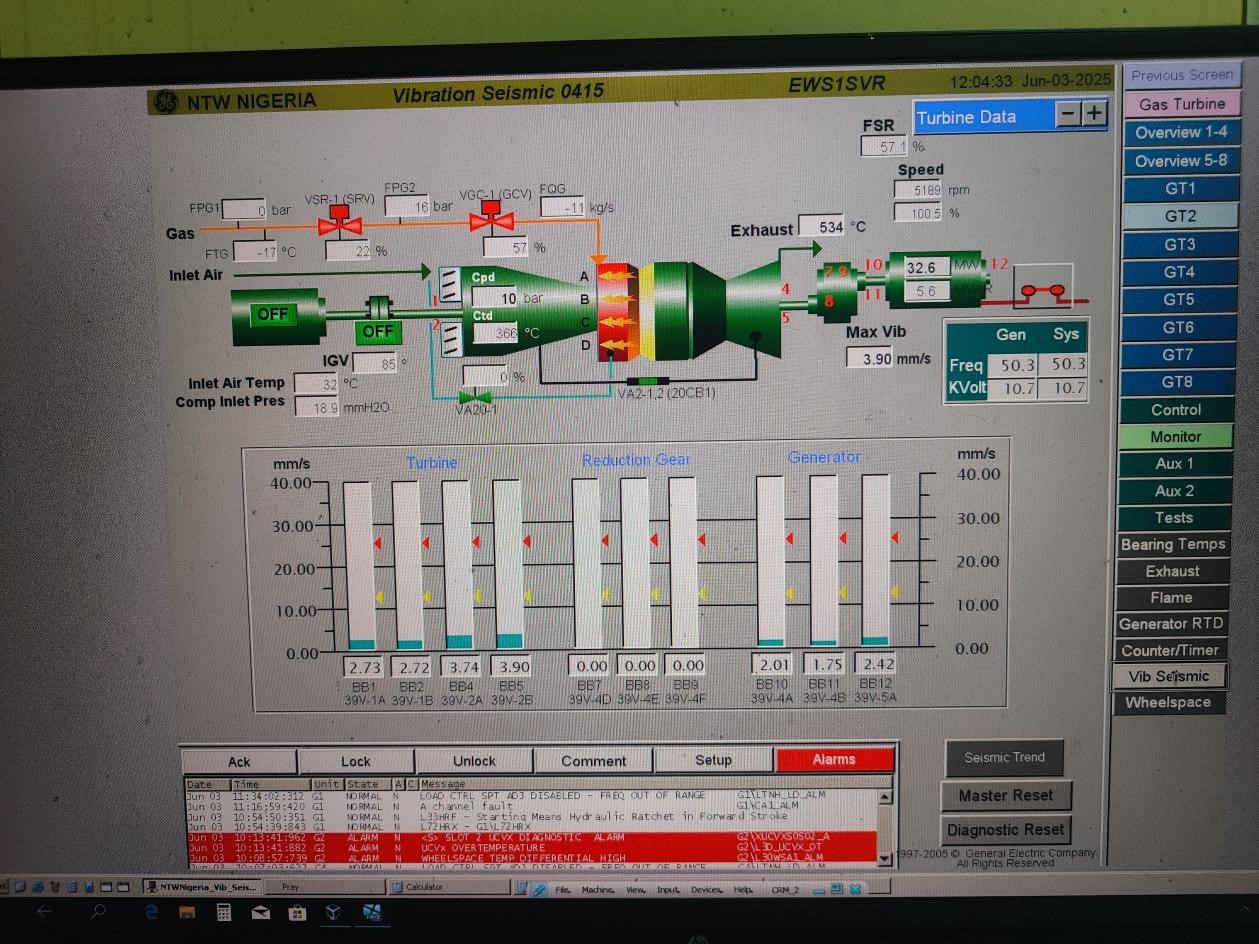

Recently, the Omotosho Project Department of Yufeng Company successfully completed the overhaul of the No. 2 GT (PG6581 GT) that has been in service for more than ten years. At present, the unit has entered the full-load trial operation state, and all parameters are running stably. This is the company's second large-scale GT overhaul project independently undertaken and completed, marking that the company has achieved a key technological breakthrough in the field of high-end operation and maintenance of GTs, laying a solid foundation for undertaking similar complex maintenance tasks in the future.

Fully cope with multiple challenges. The GT has been in continuous operation for more than ten years since the power plant was put into operation, far exceeding the conventional overhaul cycle, resulting in serious aging and rusting of core components, and a significant decline in operating performance. More challenging is that the equipment model is early, many key spare parts have been discontinued, and the difficulty and technical threshold of maintenance have been greatly increased.

In response to this situation, the company quickly established a special technical research team. Under the premise of no original or third-party technical support, relying on independent technical accumulation, it comprehensively evaluated the status of the unit and formulated a detailed overhaul plan. The team actively coordinated resources from all parties and successfully found high-quality replacement parts from the local market and domestic and foreign supply chains, providing strong guarantees for the smooth progress of the overhaul.

Independently overcome industry problems. This overhaul covers key operating links such as compressor blade repair, combustion chamber inspection, and rotor dynamic balancing correction, which are extremely technically difficult. Engineers used advanced detection technology and combined with self-developed repair processes to successfully restore the performance of the unit, and various operating indicators were close to the factory design level.

The project engineer said, "We independently completed the entire process from disassembly, inspection to installation and commissioning without the support of the original manufacturer. This is not only a comprehensive test of our technical capabilities, but also a practical test of team collaboration and resource integration."

The successful completion of this overhaul not only effectively avoided the risk of unplanned downtime caused by aging equipment in the power plant, but also significantly reduced the owner's maintenance costs. At the same time, it demonstrated the company's technical depth and execution in the field of GT operation and maintenance, and also provided the industry with a model case of independent overhaul of old units. In the future, Yufeng Power will continue to promote technological innovation, deepen high-end operation and maintenance service capabilities, and strive to provide customers with more efficient and economical full life cycle solutions for energy equipment.